Maximum pressure: 40 bar

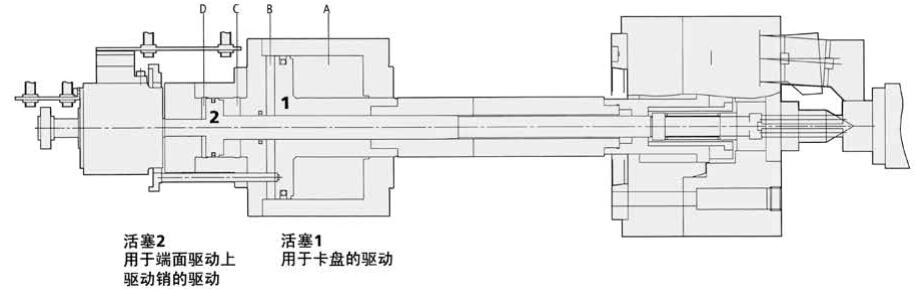

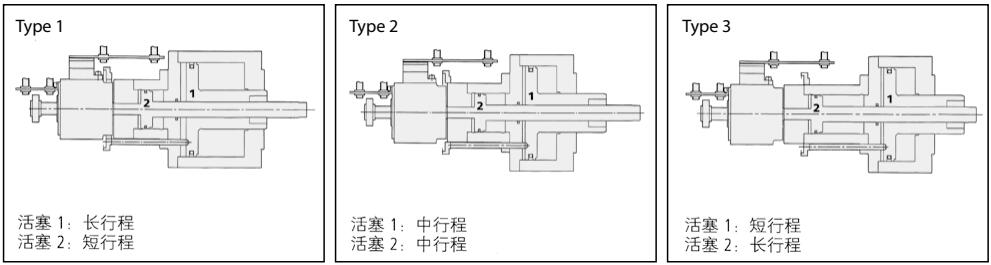

Modular design - in order to obtain different piston strokes

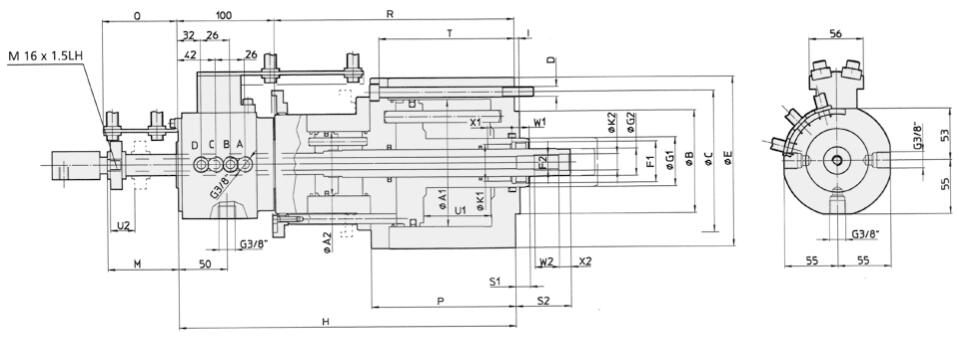

The central hole - used for conveying air, cooling fluid or oil

The stroke can be controlled through proximity switch or LPS

Maximum pressure: 40 bar

Modular design - in order to obtain different piston strokes

The central hole - used for conveying air, cooling fluid or oil

The stroke can be controlled through proximity switch or LPS

Drive the adjustable claw chuck driven by power drive end face

Power chuck with part pop-up device

Power chuck with axial telescopic positioning/finger type chuck with power driven centering device

TPT-C series chuck with double sliding sleeve action

Double piston oil cylinder has oil distribution ring with 4 lines, and is used for separate drive of each cylinder

Pressure range: 8-40bar

Module system with different piston strokes: DCN, DCU and DCR

Each oil cylinder has stroke control;large oil cylinder has a safety valve

Center hole is used for transportation of cooling liquid, oil or air , and with the thread used to install rotary joint

Horizontal or vertical installation, installation method: fixed from behind by screw

Transition accuracy requirement OF hydraulic system: 10 µm

Hydraulic oil: HM322 ISO 3448

Oil cylinder BDF - used for SG or SF series

Adjustable Claw Chuck With Fixed End Face Tip Drive

| BDF-AUTOCHACK Model | 125/30 | 170/40 | 170/60 | 170/40 | ||||

| RDN 80-25 | RDN 87-40 | RDN 40-40 | RDN 40-80 | RDN 95-25 | RDN 50-48 | RDN 50-95 | ||

| Id.NO. | 33705213 | 33705214 | 33705313 | 33705413 | 33705215 | 33705315 | 33705415 | |

| Piston stroke | 80-25 | 87-40 | 40-40 | 40-80 | 95-25 | 50-48 | 50-95 | |

| Piston area A/ piston force Max. | cm2/KN | 111/77 | 111/77 | 111/77 | 111/77 | 146/102 | 146/102 | 146/102 |

| Piston area B/ piston force Max. | cm2/KN | 125/87 | 125/87 | 125/87 | 125/87 | 168/118 | 168/118 | 168/118 |

| Piston area C/ piston force Max. | cm2/KN | 27/19 | 27/19 | 27/19 | 27/19 | 36/25 | 56/39 | 36/25 |

| Piston area D/ piston force Max. | cm2/KN | 30/21 | 30/21 | 30/21 | 30/21 | 40/28 | 60/42 | 40/28 |

| Highest rotating speed | r.p.m. | 5000 | 5000 | 5000 | 5000 | 4000 | 4000 | 4000 |

| Weight | kg | 23.2 | 24 | 22.5 | 23 | 32 | 30 | 31 |

| Rotary inertia J | kgm2 | 0.088 | 0.091 | 0.085 | 0.087 | 0.15 | 0.14 | 0.14 |

| Working pressure Max. | bar | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| Working pressure Min. | bar | 8 | 8 | 8 | 8 | 8 | 8 | 8 |

| BDF-AUTOCHACK Model | 125/30 | 170/40 | 170/60 | 170/40 | |||||

| RDN 80-25 | RDN 87-40 | RDN 40-40 | RDN 40-80 | RDN 95-25 | RDN 50-48 | RDN 50-95 | |||

| Piston diameter 1 | A1 | mm | 130 | 130 | 130 | 130 | 150 | 150 | 150 |

| Piston diameter 2 | A2 | mm | 66 | 66 | 66 | 66 | 75 | 90 | 75 |

| Positioning seam allowance h6 | B | mm | 105 | 105 | 105 | 105 | 120 | 120 | 120 |

| Position of mounting screw | C | mm | 145 | 145 | 145 | 145 | 175 | 175 | 175 |

| Mounting screw | D | mm | 6xM10 | 6xM10 | 6xM10 | 6xM10 | 6xM12 | 6xM12 | 6xM12 |

| E | mm | 174 | 174 | 174 | 174 | 204 | 204 | 204 | |

| Piston rod screw thread 1 | F1 | mm | M42x1.5 | M42x1.5 | M42x1.5 | M42x1.5 | M45x1.5 | M45x1.5 | M45x1.5 |

| Piston rod screw thread 2 | F2 | mm | M16 | M16 | M16 | M16 | M20 | M20 | M20 |

| G1 | mm | 50 | 50 | 50 | 50 | 60 | 60 | 60 | |

| G2 | mm | 28 | 28 | 28 | 28 | 30 | 30 | 30 | |

| H | mm | 38 | 380 | 333 | 373 | 411 | 366 | 411 | |

| I | mm | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |

| K1 | mm | 38 | 38 | 38 | 38 | 42 | 42 | 42 | |

| K2 | mm | 16.5 | 16.5 | 16.5 | 16.5 | 22 | 22 | 22 | |

| Max. | M | mm | 73 | 73 | 73 | 103 | 73 | 73 | 118 |

| P | mm | 150 | 167 | 120 | 120 | 184 | 139 | 139 | |

| Q | mm | 77 | 77 | 77 | 107 | 77 | 77 | 122 | |

| R | mm | 248 | 280 | 233 | 273 | 306 | 266 | 311 | |

| Min. | S1 | mm | 15 | 15 | 45 | 45 | 15 | 60 | 60 |

| Min. | S2 | mm | 57 | 75 | 72 | 82 | 73 | 118 | 73 |

| T | mm | 140 | 157 | 110 | 110 | 172 | 127 | 127 | |

| U1 | mm | 70 | 87 | 40 | 40 | 95 | 50 | 50 | |

| U2 | mm | 25 | 40 | 40 | 80 | 50 | 48 | 95 | |

| W1 | mm | 18 | 18 | 18 | 18 | 42 | 42 | 42 | |

| W2 | mm | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| X1 | mm | 25 | 25 | 25 | 25 | 10 | 10 | 10 | |

| X2 | mm | 12 | 12 | 12 | 12 | 12 | 12 | 12 | |

The above data are the standard parameters, personalized customized solutions can be provided according to customer's requirement.

Our products mainly serve major

machine tool manufacturers, major

machinery parts manufacturing companies and professional

manufacturers in various machinery

and equipment fields.

Ms Crystal:

E-mail:sales08@bdfkp.com

Mobile phone:+0086 18112891788

Ms wendy:

E-mail:wendyliu@bdfkp.com

Mobile phone:+0086 18151985123

Lily Zhao:

E-mail:sales07@bdfkp.com

Mobile phone:+0086 18118335567

YulongWu:

E-mail:sales06@bdfkp.com

Mobile phone:+0086 18151972789