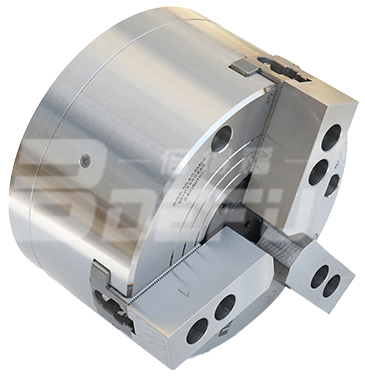

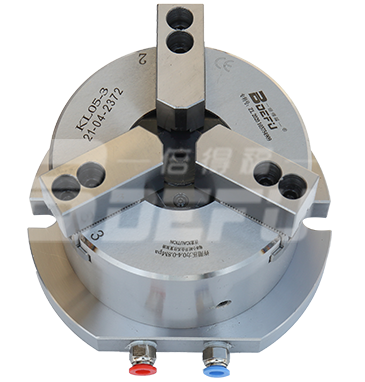

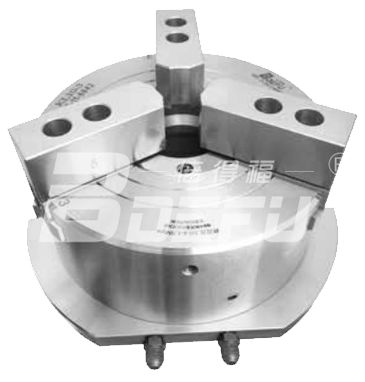

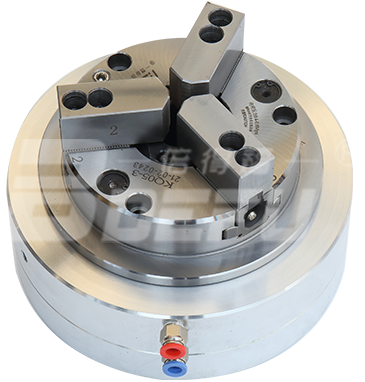

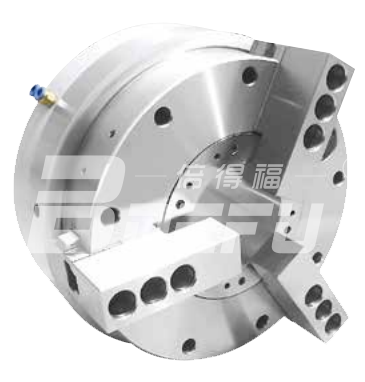

KQ Front-mounted pneumatic chuck

Short cylinder rear-lock screw connection form

The chuck is easily installed, and its connection method follows industry standards, without having to change the original machine tool structure; the cylinder and chuck are integrated and designed, and one chuck can be mounted in front of and at the back of machine tools respectively to use at the same time.

The chuck has a big bore diameter, and contains a one-way valve and has the function of reliable clamping; while the chuck is rotating, the sealing device is in the disengaged position, so it has a long service life

Working principle: the clamping power source of the chuck is compressed air; when compressed air flows into the one-way valve through a distributing ring and then into the chuck cylinder, thus to drive the piston, so that the jaw clips a workpiece tightly; then, the reversing valve is powered off, and the air pressure within the cylinder is sealed by the one-way valve. The sealing device of the distributing ring is released, not to contact the chuck body, and the equipment

can be started for normal work at this time.

Note: because the chuck is ventilated in the clamping and released state, and the special sealing element on the distributing ring clamps the excircle of the chuck body tightly, so the machine tool spindle should stop rotating while the chuck is clamping and releasing the workpiece.

With two functions of clamping and holding.

When front-locking connection form is required, contact us before ordering

ZL 2015 10398341.3